As the world’s largest producer of oil, Saudi Aramco has a unique responsibility to provide global markets with a reliable and secure supply of crude. At the company’s Research and Development Center in Dhahran, Aramco scientists are pioneering the use of robots to help maintain and inspect the company’s assets, while developing advanced non-metallic materials for applications in the oil sector and beyond.

Q&A with Ihsan M. Al-Taie, Chief Technologist, Oil & Gas Network Integrity R&D Division, Research & Development Center, Saudi Aramco

How is Saudi Aramco using robotics to ensure asset integrity?

Our network of pipelines and facilities spreads all over the Kingdom from the Red Sea to the Gulf Coast and includes water systems as well as crude and gas lines. To help us inspect this network, we have developed our own robots for offshore (SWIM-R) and onshore (SAIR) deployment, as well as sensors that can detect crude products.

Our Shallow Water Inspection and Monitoring Robot (SWIM-R) enhances pipeline inspection speed, efficiency, and safety. It is remotely operated to perform underwater inspection tasks in shallow water environments, which can prove difficult for traditional diving support vessels.

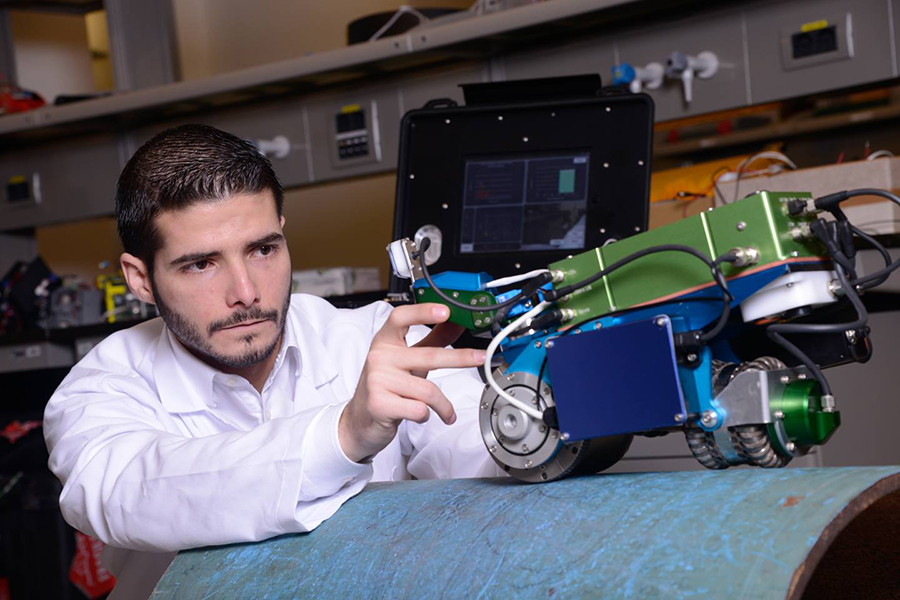

The Saudi Aramco Inspection Robot (SAIR) is a magnetic robotic crawler capable of conducting visual inspection, ultrasonic thickness gauging and gas sensing on hard-to-reach steel surfaces. It reduces potential hazards, inspection times and costs. Rather than putting up scaffolding for inspection activities, we can send the robot up to the pipeline and it provides data wirelessly. This reduces the cost of operation and helps maximize our margins.

Tell us more about the people working on robotics at Saudi Aramco.

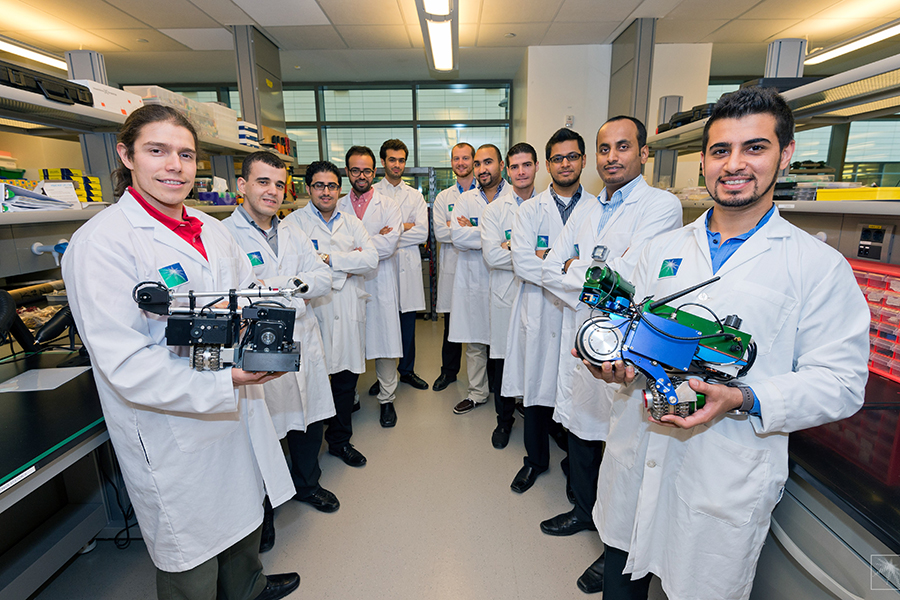

Our robotics team is made up of talented young people from all over the world, and in one team no two people are the same nationality. In my team we have the highest percentage of female research scientists in the workforce.

All team members are talented graduates from the King Abdullah University of Science and Technology (KAUST). Thanks to their skills, we can produce highly competitive robotic products. For instance, for each robot we hold between seven and ten patents, depending on the complexity of the robot.

What is the current research focus of your robotics team?

Until now our focus has been on external inspection of pipes. Now we are going into the pipe itself. We have a robot that can operate inside 6-inch diameter pipes for welding, coating repair and inspection. This technology is not available in the market the way we want it, so we are developing it and we have already made good progress.

“In the packaging sector, we are currently developing technologies that can trigger the degradation of the materials to non-harmful chemicals, so that if you throw a bottle of water into the sea, the plastic will start to degrade at a certain degree of salinity.”

Ihsan M. Al-Taie, Chief Technologist, Oil & Gas Network Integrity R&D Division, Research & Development Center, Saudi Aramco

How can Industry 4.0 help you ensure asset integrity?

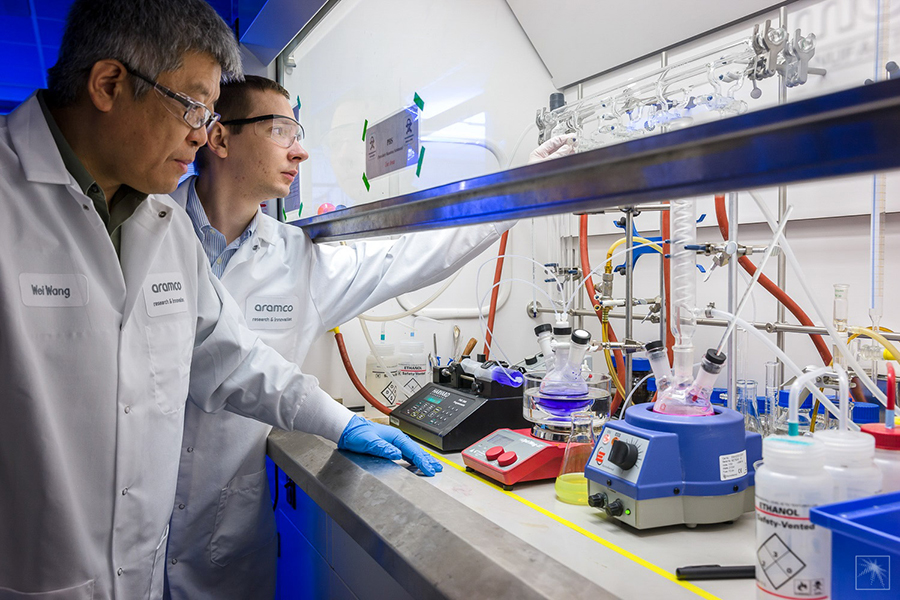

Industry 4.0 is all about data. We are currently working at the foundation level to develop the sensing systems to generate the data. The next step is what to do with the data, so we develop modelling software that can analyze the collected data and make predictive decisions. We convert the physical assets into digital data and use that to make intelligent decisions. We have combined this with machine learning capabilities. We have established strong foundations for the future.

Moving to another area, why is Saudi Aramco focusing on non-metallic materials?

Non-metallic materials represent a great opportunity to increase global crude demand, as they are formed by converting crude into chemicals. Our goal is to lead the non-metallic materials business globally and to create demand for these chemicals, particularly polymers.

In Saudi Aramco we are developing applications that will create the demand for composite materials in the oil and gas industry and four other sectors: automotive, building & construction, packaging, and renewable energy. We are working to lower the cost of carbon fiber and carbon fiber reinforced plastics for the automotive industry. For the construction industry, we are developing fire-retardant materials and working on replacing steel rebars with CFRP (Carbon Fiber Reinforced Polymer) rebars.

In the packaging sector, we are currently developing technologies that can trigger the degradation of the materials to non-harmful chemicals, so that if you throw a bottle of water into the sea, the plastic will start to degrade at a certain degree of salinity.

Another exciting topic is that we are developing hybrid materials which could one day replace the glass used by solar panels.

Focusing on the oil industry, what are the advantages of non-metallic materials?

By replacing steel pipes with non-metallic materials, you can eliminate corrosion. These materials do not corrode. They degrade in a different way but in the overall life cycle they are much more cost effective than steel.

In the oil and gas sector, we have been using steel for more than a century and we fight the corrosion of steel pipes in the industry by injecting corrosion inhibitors, coating, inspections, and so on. Now it is time to replace the steel with composite materials wherever it is possible.

The challenge is that steel is still the material of choice, particularly in large-diameter pipes. So we are working on a solution whereby we produce large-diameter, high-temperature materials that can withstand the demanding environment of the industry, all at a reasonable cost.

To optimize costs, we are working on ways to reduce the energy required to produce carbon fiber. We are also looking at how we can use different feedstock from refineries. We are working towards lowering the cost of carbon fiber so that other manufacturers can afford to swap steel and aluminum with non-metallics.

Finally, how has the role of R&D at Saudi Aramco changed since you joined the company?

Today we have a strong track record of rapid technology development. Looking to the wider ecosystem, in the past some companies may have been reluctant to collaborate with us on technology development as they considered us to be mainly a technology buyer.

Today, they consider us as partners in technology development and innovation![]()